Transport monitoring

Transport monitoring systems are designed to monitor the operation of equipment in various conditions.

Mines – control of the underground park without having access to the GSM network;

Careers – monitoring of heavy quarry equipment;

Production sites with a private fleet

With the introduction of transport monitoring systems, you get an increase in the efficiency of equipment and a reduction in unplanned expenses for the maintenance of the fleet.

We offer you

«Business Engineering KZ» offers several types of vehicle monitoring systems:

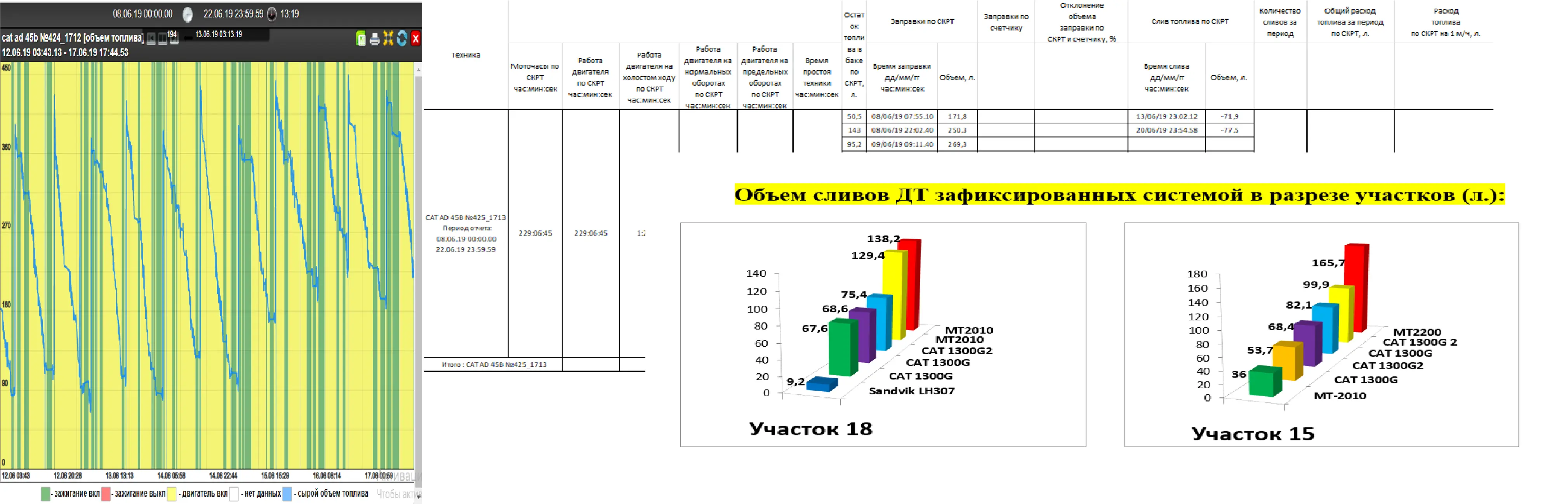

Fuel consumption monitoring system

FCMS - this tool helps to establish the facts of the discharge of diesel fuel from the tanks of vehicles, the facts of refueling and the amount of refueled fuel (which excludes entries in the company's statement and receipts), keep records of average fuel consumption for each unit of equipment. This function helps to save on the purchase of fuel and the eradication of theft and attribution from fuel suppliers.

The main purpose of the system is to provide objective rationing of fuel consumption at the stages:

- arrival of fuel to warehouses;

- equipment of vehicles;

- fuel consumption and targeted use of equipment

The system allows you to control:

- for current fuel balances in warehouses;

- for the current remaining fuel in the tanks of vehicles;

- monitoring fuel consumption on each trip;

- overspending of fuel;

- for unauthorized use of equipment;

- for fuel shortages by suppliers;

- monitoring fuel consumption throughout the entire transport fleet.

With the help of fuel level sensors installed in the fuel tank, you can see refueling, draining and the actual amount of fuel for a particular period of time

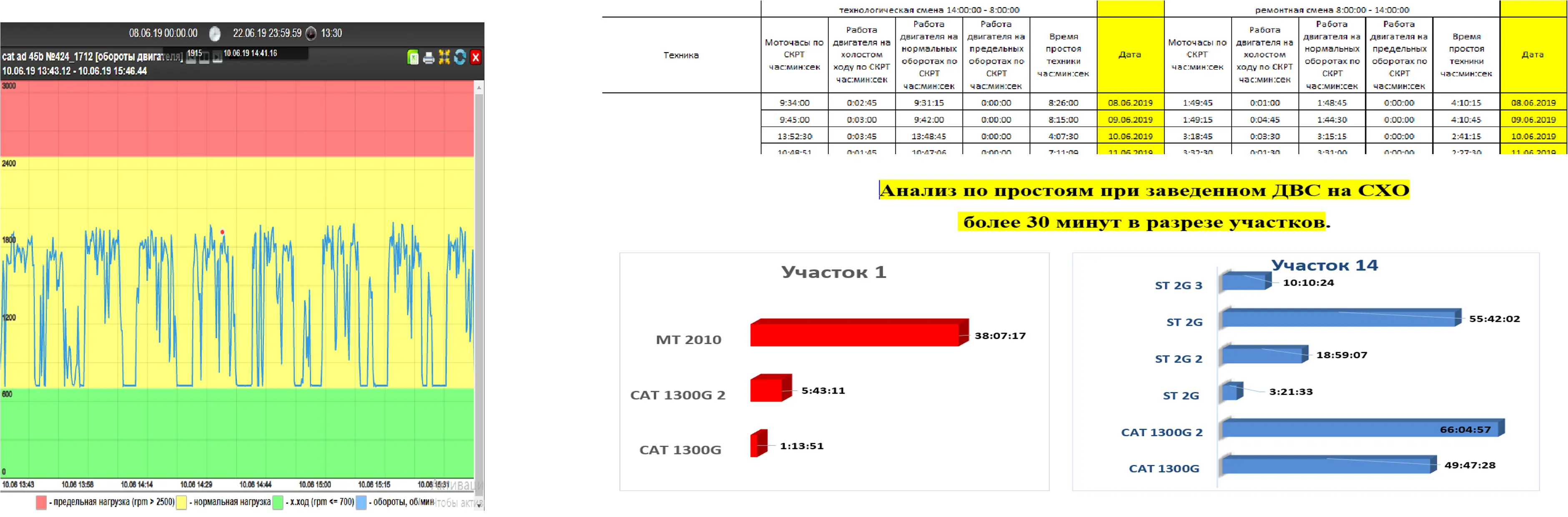

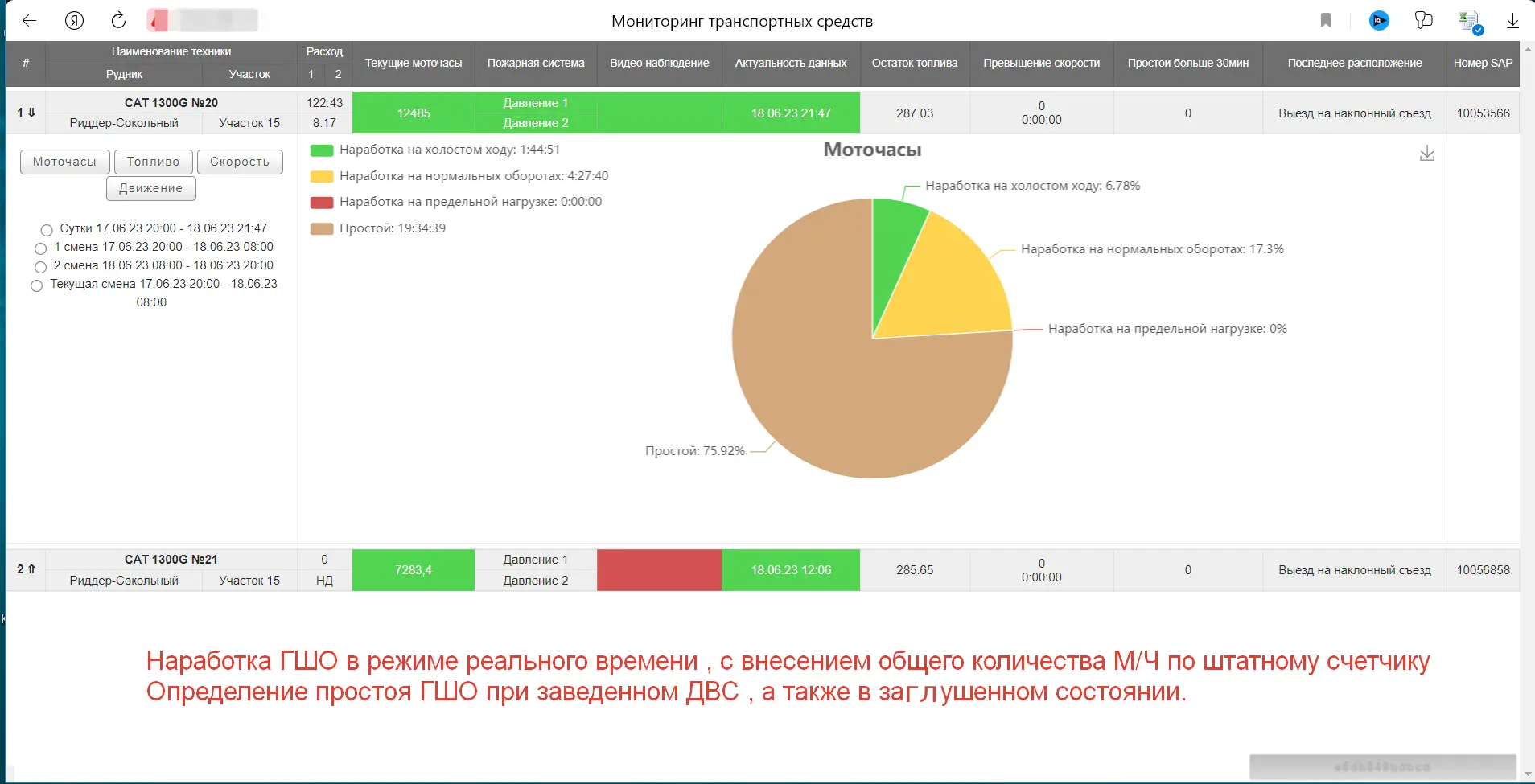

Monitoring of engine operating hours

Monitoring of engine operating hours – helps to monitor the actual operation of the engine in different modes. This function helps to identify:

- General downtime of equipment;

- Idle equipment downtime;

- Engine operation at normal rpm;

- Engine operation at maximum rpm;

Also, to keep an actual calculation of engine hours, as a result of which it is possible to plan maintenance on the actually spent engine hours, which reduces the cost of maintenance, and also confirms the need to replace consumables and basic equipment units.

The engine speed is read on the connected equipment, displayed in the software in the form of graphs, after which a report is generated on the accumulated motorcycle hours and equipment downtime.

Preparation of flexible analytical reports

Example of displaying necessary diagrams in software.

Tire pressure monitoring

TPM – tire pressure monitoring system, performing tire pressure monitoring, primarily cares about the safety of the driver and passengers, also the system will automatically detect and warn the driver in case of an emergency situation and help avoid unpleasant consequences.

- Optimal and uniform tire wear is ensured by evenly distributed tire pressure, which ensures maximum tire walking. Over-inflated or under-inflated tires do not allow to achieve perfect contact with the coating, which leads to uneven wear and shortened service life.

- Performing the function of a driver's assistant, it helps to avoid wheel losses, actively contributing to their «salvation».

- By controlling the tire pressure, it will help to avoid unpleasant situations by notifying the driver of the occurrence of insufficient or excessive pressure, significantly reducing the risk of tire explosion.

- Thanks to the tire pressure monitoring system, it is possible to significantly reduce the number of side wheel breakdowns, which is a key factor in saving radial tires.

- By maintaining the optimal recommended tire pressure, thereby reducing the rolling resistance of the wheel and achieving the normative coefficient of adhesion of the rubber to the road, it is possible to achieve fuel economy on average from 1 to 3%.

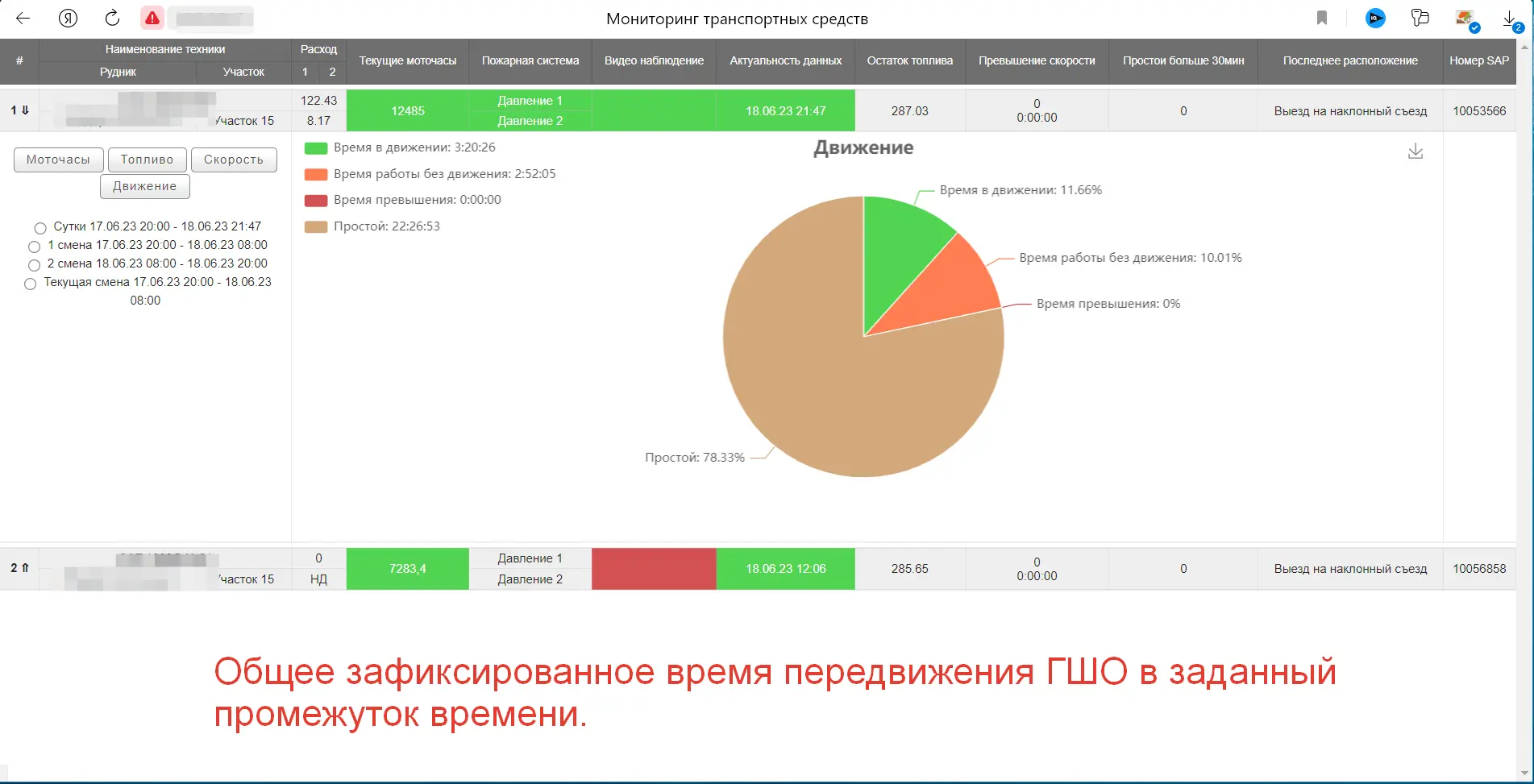

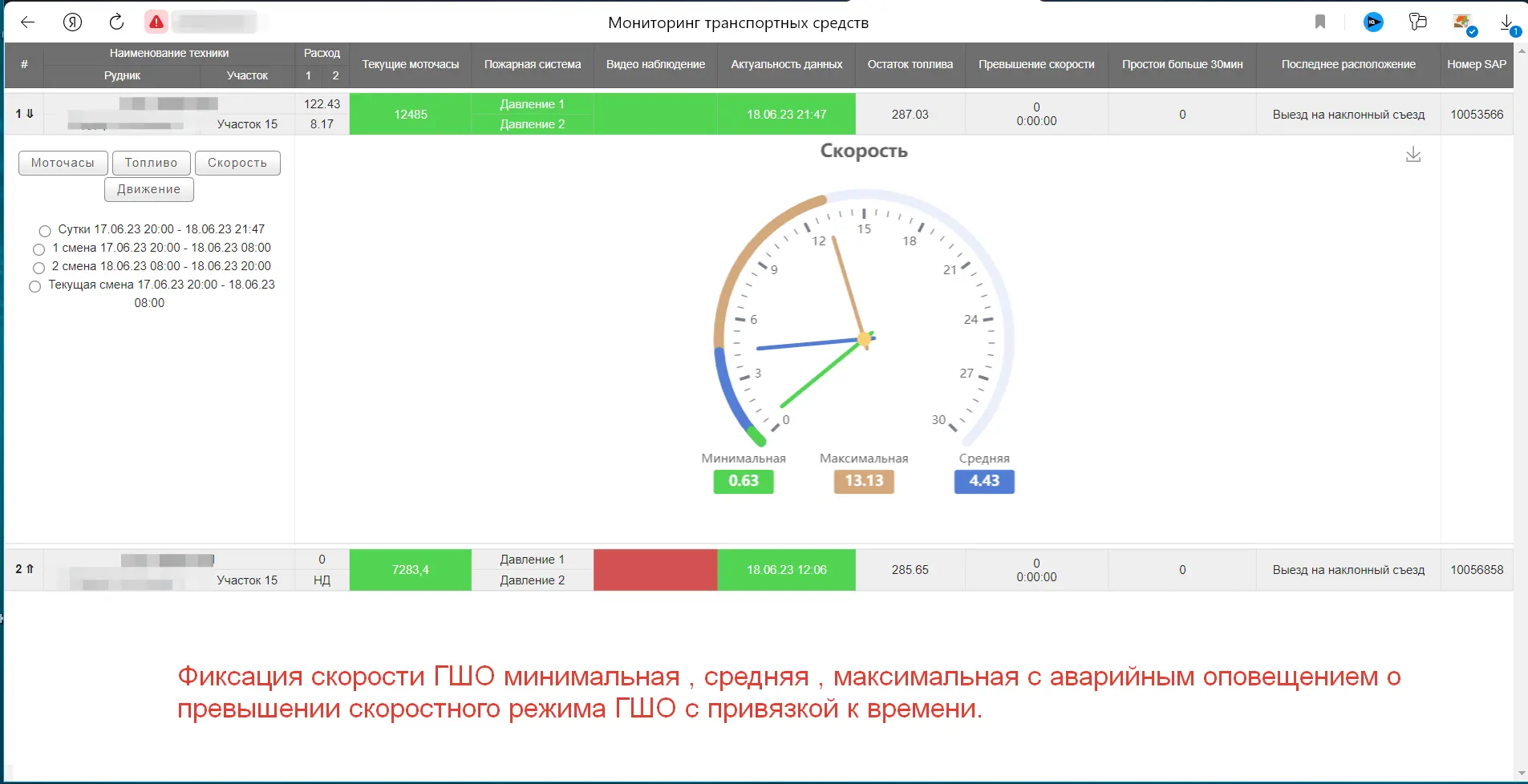

Transport monitoring system

The system allows you to track the location, speed, direction of movement and other characteristics of vehicles.

Monitoring of all of the above systems helps to identify negligent attitude on the part of the staff to the equipment used, which leads to inappropriate costs for the maintenance of the park.

Our team combined all these systems into a single tool for monitoring equipment, which helped to create a system of total control of the fleet.

Also, our company has its own analytics department, which employs professionals who are able to identify problems with the operation of the fleet in the shortest possible time and provide reports for management, which allows you to make decisions on the management of equipment in the shortest possible time.

With the introduction of our systems, you will be able to increase the efficiency of your fleet by reducing downtime, attributions, as well as reduce the cost of maintaining the fleet by increasing efficiency and reducing the cost of maintenance and repair of equipment.

Диспетчеризации горно-шахтной техники

Повышение эффективности работы активов путем оптимизации бизнес процессов.

Диспетчеризация - является инструментом при помощи которого будут приниматься управленческие и операционные решения по достижению оптимальных условий эксплуатации оборудования в максимально кратчайшие сроки.

BEKZ - Solution Of Non-Standard Tasks

The company Business Engineering KZ has been successfully implementing vehicle monitoring projects, as well as providing technical support since 2012. During this period, the Company has accumulated extensive experience working with transport monitoring systems.The goal of our company is to solve all kinds of problems of our Customers.

More700+

cars40%

fuel economy70%

cost reduction24/7

supportAny questions?

Do not hesitate to contact us for answers and professional support!

Mon–Fri from 8:00 – 17:00

Sat from 8:00 – 12:00

Sun – day off

Почта: info@bekz.kz

Frequently Asked Questions

Find quick and clear answers to the most common queries here.

The cost of equipment?

The cost of the equipment depends on the customer's task and the selection of equipment for its solution.

What is the effectiveness of the FCMS project?

The first effect of the implementation of this project can be obtained after a week of its operation, thanks to the accuracy of providing analytical reports.

How does the system work if there is no connection?

Our equipment allows you to record information for more than 2 weeks, and at the first successful connection transmits it to the server